Republic Cement Pioneers Use of Data Science in Philippine Cement Manufacturing

- Republic Cement

- Oct 1, 2021

- 5 min read

For sixty-five years, Republic Cement has been and continues to be the proud maker of the best quality locally manufactured cement and building materials in the Philippines. Across its seven sites nationwide (5 fully integrated cement plants, 1 grinding station, and headquarters), Republic is a company built by over 1,000 of the brightest minds and most forward thinkers in the industry.

Republic Cement’s innovation journey is not new. The company has always pushed for growth through innovation as a means for sustainability at every step of the manufacturing process. Whether this is by introducing new products to the market, new ways of bringing customers better service, or by changing the way things have been traditionally done in cement operations. This is admittedly very challenging in an industry where the main product has been made the same way for centuries. So why fix something that isn’t broken?

In line with the company’s mission to deliver the best products the best possible way to serve the Filipino consumer, Republic seeks to do its part in building the nation for the generations to come. Through the different digital transformation initiatives across the company, Republic endeavors to empower each employee to make a direct impact on its commitment to building a greener, safer, and stronger Republic.

Driving Quality through Digital Transformation

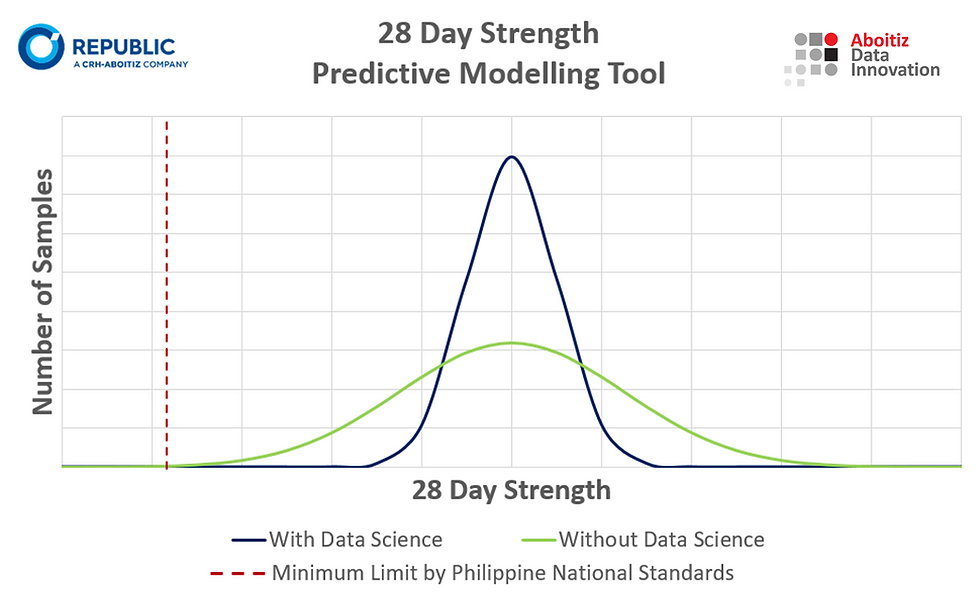

Within the past year, one of the key areas for digital transformation has been Republic’s manufacturing process. Driven by a mission to deliver the best quality products to customers, Republic’s Data Scientists, in partnership with Aboitiz Data Innovation, have developed a 28-Day Strength Prediction Tool that uses data science and artificial intelligence to cut CO2 emissions and allows the company to produce stronger and more consistent cement.

The strength of cement is typically measured only after a 28-day waiting period, wherein representative samples of cement are molded into cubes, cured, and tested for its compressive strength using a compression strength testing machine. Since cement was reinvented in the late 1800s, cement strength has been traditionally determined through this process. This test is also conducted to ensure compliance with the Philippine National Standards as well as the standards required by the project. While the process is a commonly accepted practice, Republic Cement posed the questions: Is it possible to eliminate this wait time and find out compressive strength immediately? How would it affect the manufacturing process, the customer’s projects, and the cement industry as a whole? Would it change the way that things have always been done for the better?

To begin working towards this, Republic Cement put in place a comprehensive data infrastructure to collect relevant data about the various states and chemical compounds present in cement across the whole manufacturing process and identifying its qualities after curing for 28 days. Further to just collecting and digitizing Republic’s data, there was also a need to process this data into relevant information.

In exploring how to turn its data into relevant information, Republic Cement teamed up with Aboitiz Data Science (ADI) to build an Artificial Intelligence (AI) tool for its cement manufacturing operations. The product is designed as a DSAI application to help operators and quality managers optimize concentrations of raw ingredients in the cement mix by instantly harnessing complex algorithms, thus saving time and resources. The development of the product also led to innovative data-driven adjustments making it important for the company to embed the tool as part of daily operations.

“The application of DSAI in Cement is extremely exciting as it demonstrates that DSAI can be a core differentiator in traditional industries while also allowing them to flourish digitally. This is just the start, our focus is to innovate and systematically operationalize DSAI benefits in areas such as customer engagement, operations and in materializing ESG [Environmental, Social, and Corporate Governance] goals,” said Dr. David R. Hardoon, Aboitiz Data Innovation Managing Director.

Artificial Intelligence Yields Real Results

As of September 2021, four of Republic’s plants are now utilizing the AI tool. Improvements to the current model are underway, with continuous remodeling informing ongoing rollouts to the remaining sites. Since the first site rollout in July 2020, the tool is on track for full rollout by yearend.

Republic has since been able to improve the quality of its products by producing cement that consistently exceeds the strength requirements of Philippine National Standards. Through this tool, the company is able to correlate a wide number of factors and eliminate the subjective adjustments that chemists and engineers were required to make to meet the strength targets. These adjustments are now made in a more scientific and structured way using data science. Customers are also assured of higher consistency in strength with all Republic Cement products nationwide, leading to efficient concrete design.

Republic has always sought to reduce CO2 emissions through manufacturing greener cement. Through the application of the tool and being able to accurately predict 28-day cement strength, the company has been able to further optimize its manufacturing process. By better managing resources and increased efficiency of raw materials, an additional reduction of 35,000 tons of CO2 emissions annually was realized.

Republic Cement’s VP for Manufacturing Lloyd Vicente shared “Sustainability and building a greener environment for generations to come remains a top priority at Republic Cement. Through this, we intend to do our part in restoring and preserving our environment while producing the best quality cement for the Filipino consumer.”

The Future of DSAI in Philippine Cement Manufacturing

Since the 28-Day Strength Tool was first rolled out at the first site last July 2020, Republic Data Scientists are still learning new things and important insights every day. While the initial model has been created, the tool is continuously evolving as each site grows more sophisticated in the use of the tool and new sites are onboarded.

Once all sites are smoothly running the 28-Day Strength Prediction Tool, the next step is to integrate the prediction tool into existing Process Expert Systems (PXP). This will allow for Kiln & Finish Mill Semi-Autonomous Operations through the creation of a self-learning AI that automatically adjusts operating parameters. Through this, optimal operating and manufacturing conditions will be achieved, and these activities will optimize the heart of Republic Cement’s operations, minimizing subjectivity by distilling years of knowledge and experience from seasoned Control Room Operations into this system.

As part of the bigger picture, these manufacturing initiatives are part of a bigger digitalization roadmap within Republic Cement. In encouraging innovation in all areas of the business, one such example of a program in the pipeline includes improvements in inventory management and dispatch, which would allow for seamless integration between the dispatch team and customer pickups.

“Republic has and will remain a close partner in building the nation,” said Republic Cement President & CEO Nabil Francis. “Through the use of DSAI, we intend to translate this efficiency in process into something that benefits all Filipinos and will encourage Filipino consumers to patronize local cement. It is our intention that, by further assuring consumers of the strength, quality, and consistency of cement that they are buying, that consumer confidence will also rise.” By buying locally manufactured cement, consumers inject three times more into the local economy than when buying imported cement products. This is particularly crucial as the country works towards its recover after the negative economic impact of the COVID-19 pandemic.

“These programs in DSAI are also a great opportunity to develop local talent,” added Francis. Republic Cement is currently developing the first batch of data scientists for the Philippine cement industry. “The Filipino is immensely talented and we have great potential in the country because of the resilience, creativity, and talent of its people. Republic Cement remains committed to doing its part in empowering the Filipino on its journey to building a greener and stronger Republic.”

Comments